QuinteSens

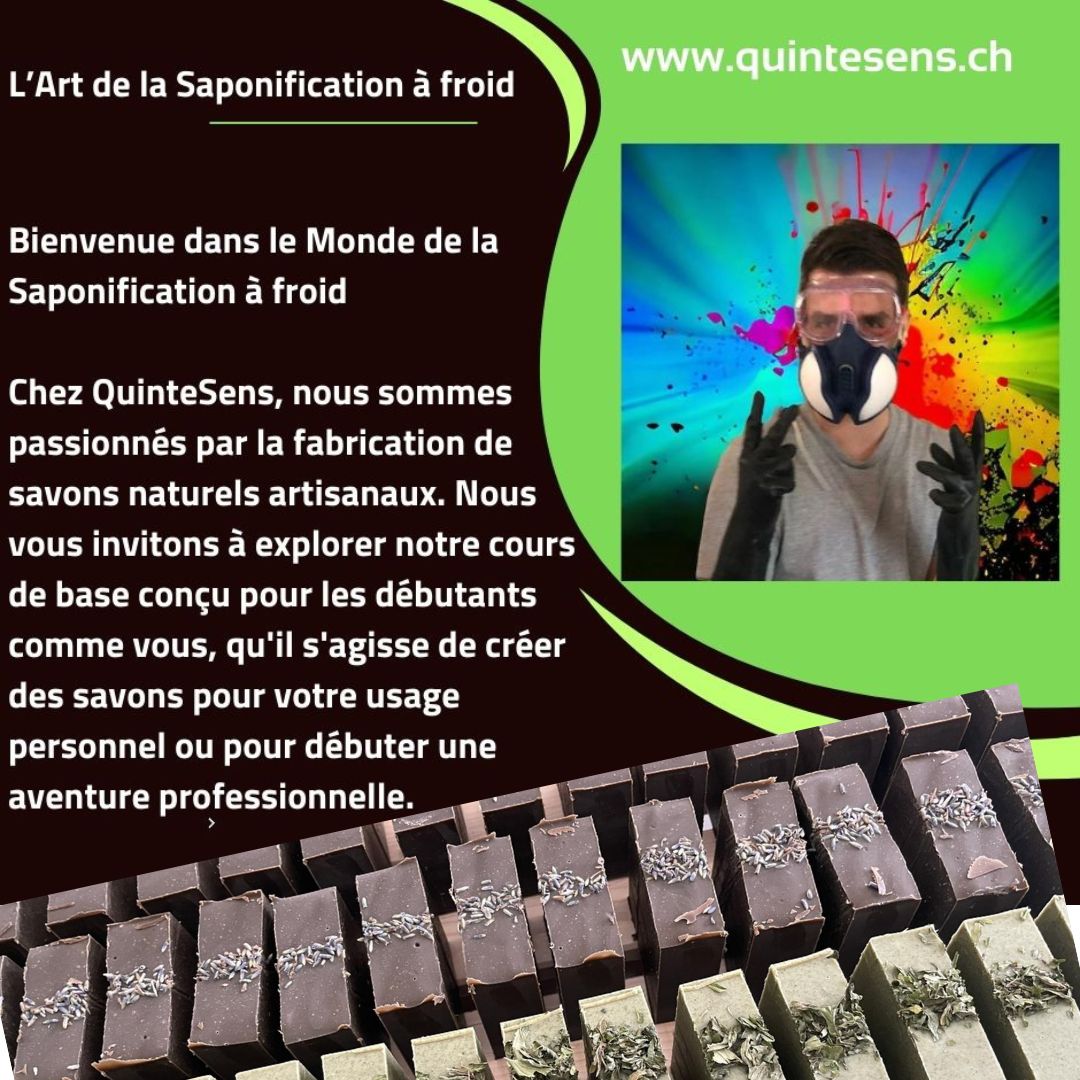

The soap school: The Art of cold saponification

The soap school: The Art of cold saponification

- Discutez avec notre assistante disponible 24-7

- Livraisons en Suisse offerte à partir de 100 CHF de commande

- Les commandes passées après 17h sont expédiées le jour suivant si pas de marché prévu.

Couldn't load pickup availability

For all those who want to discover cold saponification

The cold saponification method is the one used since the dawn of time, it allows you to work with 100% natural ingredients and offers the possibility of creating moisturizing and nourishing soaps.

Cold saponification is an artisanal soap making process. It is based on a chemical reaction between oils or fats and a chemical called caustic soda (sodium hydroxide). Here's how it works:

-

The basic ingredients:

- Oils or fats: Vegetable oils, such as olive oil, coconut oil, or palm oil, as well as animal fats, can be used to make soap. Each of these oils has its own properties that influence the texture and characteristics of the final soap.

- Caustic soda: Caustic soda is a very strong alkaline chemical substance. It is essential for transforming oils or fats into soap. However, it must be handled with care as it can be corrosive.

- Water: It is used to melt caustic soda balls to become washing soda.

-

The saponification process:

- To begin, we prepare the lye (caustic soda/water = exothermic chemical reaction) which we will allow to cool before mixing with the oils or fats in precise proportions and at the same temperature as the lye. . During this process, oil and fat molecules react with lye to form soap molecules and glycerin.

- This chemical reaction is exothermic, meaning it generates heat.

- Then the mixture is poured into one or more molds. The mixture begins to thicken and become opaque.

- This step is called "saponification".

-

Hardening of the soap:

- After 24 to 72 hours after complete saponification and depending on the soap formula which has hardened sufficiently, it can be cut into bars or individual pieces.

- The soap should now sit for several weeks. During this time, the soap hardens and loses moisture. The glycerin produced during saponification remains in the soap, making it gentle on the skin.

-

Cutting and use:

- 4 to 6 weeks later, these pieces are now ready to be used (check the PH) to wash your hands, face, or body, depending on the oils used and any additives added (such as perfumes, dyes or others).

Cold saponification is appreciated for its natural process which preserves the benefits of the oils used and allows the creation of high quality artisanal soaps. However, it is essential to take precautions when handling caustic soda due to its corrosive nature.

Share